IMAGE QUALITY IS ONE OF THE KEY FEATURES OF A LONG-RANGE OPTICAL INSTRUMENT.

HIGH IMAGE QUALITY ENSURES YOU SEE THE WORLD IN ITS MOST NATURAL FORM. FRANZ

ERLER AND DANIEL ROTTER FROM SWAROVSKI OPTIK HAVE PULLED OUT ALL THE STOPS TO

ENSURE THEIR DEVICES MEET THE VERY HIGHEST STANDARDS. THEY ALSO REVEAL HOW THEY

TEST THE IMAGE QUALITY OF BINOCULARS AND SPOTTING SCOPES.

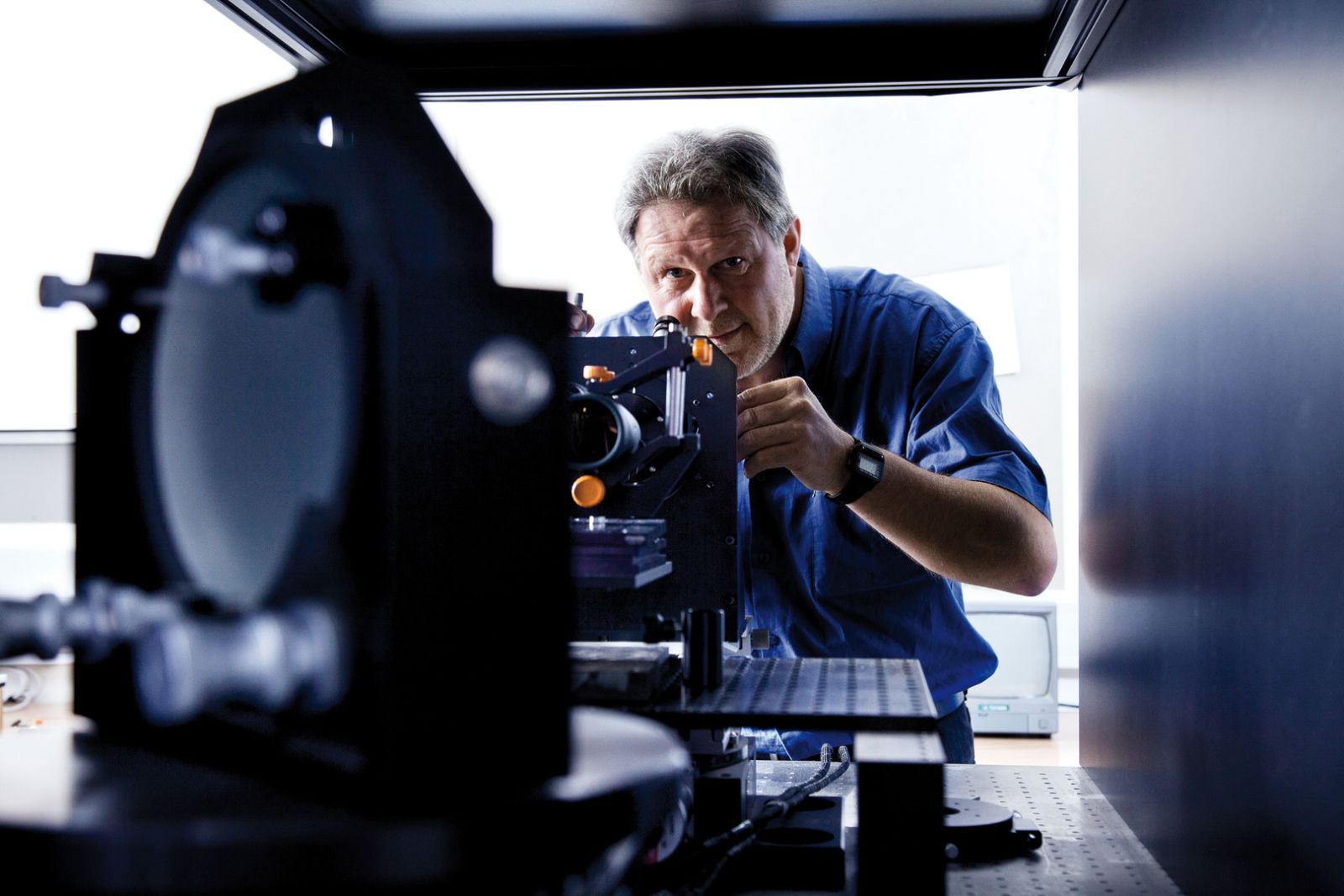

If anyone deserves to be called a “rock,” it’s Franz Erler. He joined SWAROVSKI OPTIK in 1979 and now heads up Quality Assurance, where he is currently passing on his wealth of knowledge to his successor, Daniel Rotter. These two natives of the Austrian Tyrol and their team play a vital role in ensuring that every long-range optical device manufactured in Absam meets the very highest standards. They know binoculars and spotting scopes inside out and understand exactly how to meet their customers’ expectations and requirements.

Image quality

MESMERIZED BY THE MOMENT

Image quality is what separates premium products from mass market goods. It is composed of high color fidelity, minimal color fringing, and a razorsharp image right to the edge.

“Our philosophy is to create an image of the scenery that is as precise and natural as possible – just bigger,” says Franz Erler. The idea of virtual reality glasses – often referred to with the buzzword “immersive” – has long been an issue in the field of long-range optics. “The viewer should feel connected with the moment and with nature,” stresses Daniel Rotter.

EVERY HOUR INVESTED IS VISIBLE

This requires what Erler calls a “balanced overall

optics package.” For him, this starts with clever

design, continues to manufacturing technology

involving tolerances of 1/10 of a hair’s breadth,

and moves on to regular inspections during

assembly. “It’s vital to ensure that all the different

areas and technologies are interlinked. It’s a big

help that all the technologies we need are available

at our Tyrol facility,” says Erler. “We also

take the time to make sure the product is perfect

when we launch it on the market. That’s how we

created our greatest masterpieces, such as the

EL binoculars.”

Every SWAROVSKI OPTIK product passes

through quality assurance before it leaves the

factory. The team subjects it to a rigorous set of

checks. They still use visual testing, similar to the

test card that used to be used on TV in the 1990s.

The trained eyes of the inspection team are able

to “pick out an incredible amount,” says Erler.

For high precision measurements, the optics are

tested with lasers.

However, the hard work that goes into making the best possible product is not an end in itself. High image quality allows users of the devices to immerse themselves in a beautiful moment, but it also has many practical advantages.

Color fidelity

WITH THE GAZE OF A BIRDER

In birding it is something that is crucial for correctly identifying bird species, which can often only be distinguished through slight differences in their color, shape, or size. The natural representation of colors – color fidelity – is vital for birders.

TECHNOLOGY IS HUMAN

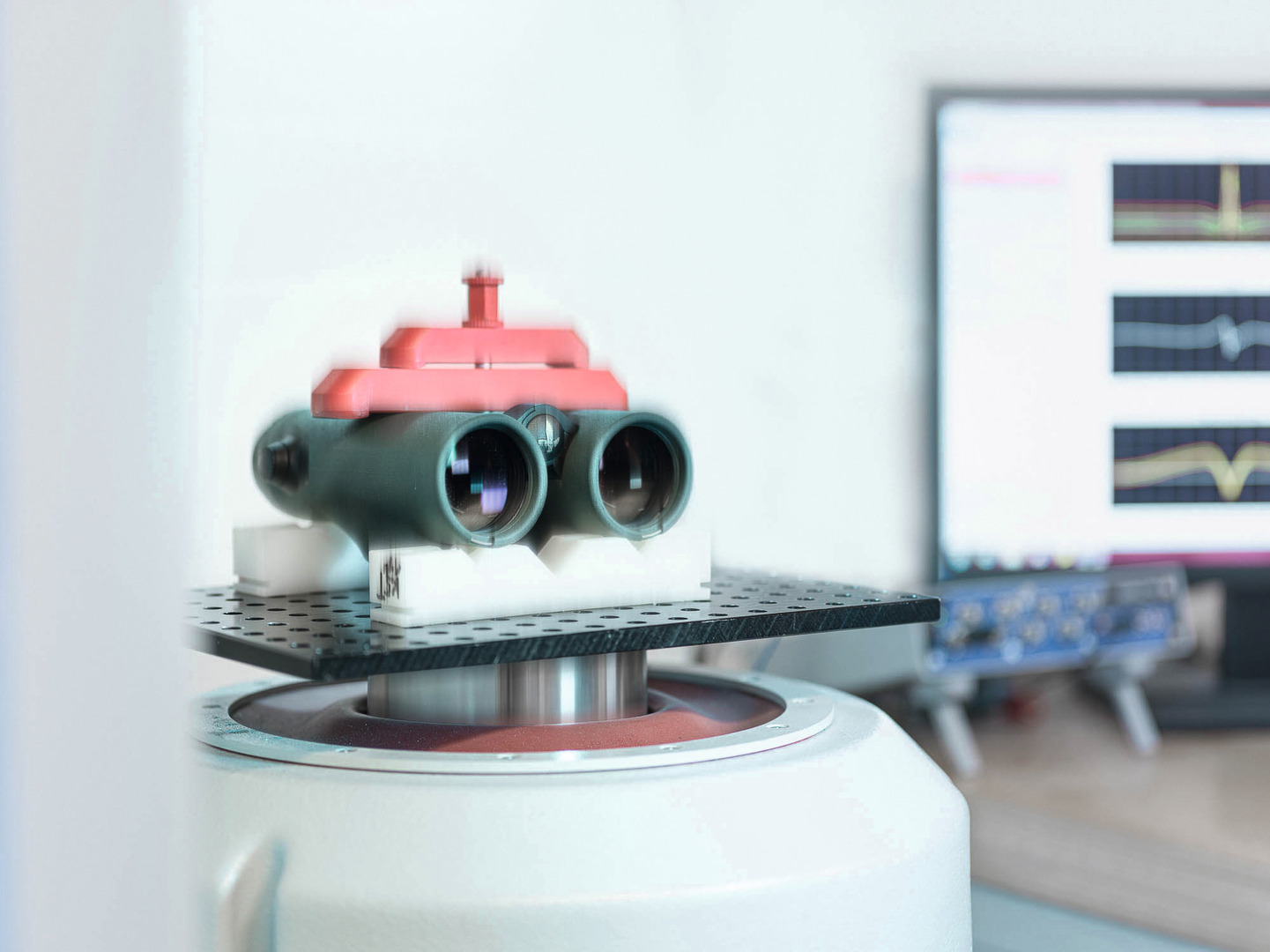

“Delivering the best possible image quality means

top-quality components, from lenses and prisms

to the tiniest mechanical parts,” says Daniel Rotter.

An example of this is again the EL binoculars, which

combine the whole optical package that Franz Erler

referred to at the beginning. They have field flattener

lenses to flatten the image, coatings to optimize the

color rendering, and an HD optical system with

fluoride-containing lenses to minimize color fringing

while increasing resolution and contrast.

So are we at the end of the journey? Have we reached absolute perfection in terms of image quality? “We’re already very close to perfection,” says Franz Erler, “but it’s always possible to tweak it a little more.” Daniel Rotter points to the latest trends in technology: new types of glass, better lubricants and auxiliary materials, the use of magnesium for housings, new surface coatings, and increasingly precise manufacturing processes have revolutionized long-range optics in recent years. For him, the most exciting development at the moment is “aspherical lenses,” which are already being used in smartphone cameras.

But they both agree that what matters most is the

people behind the products. “The desire of the

project team to build the best device in the world

is a hugely important factor,” says Erler. “In other

words: technology can only be as good as the

people who produce it.”